Introduction

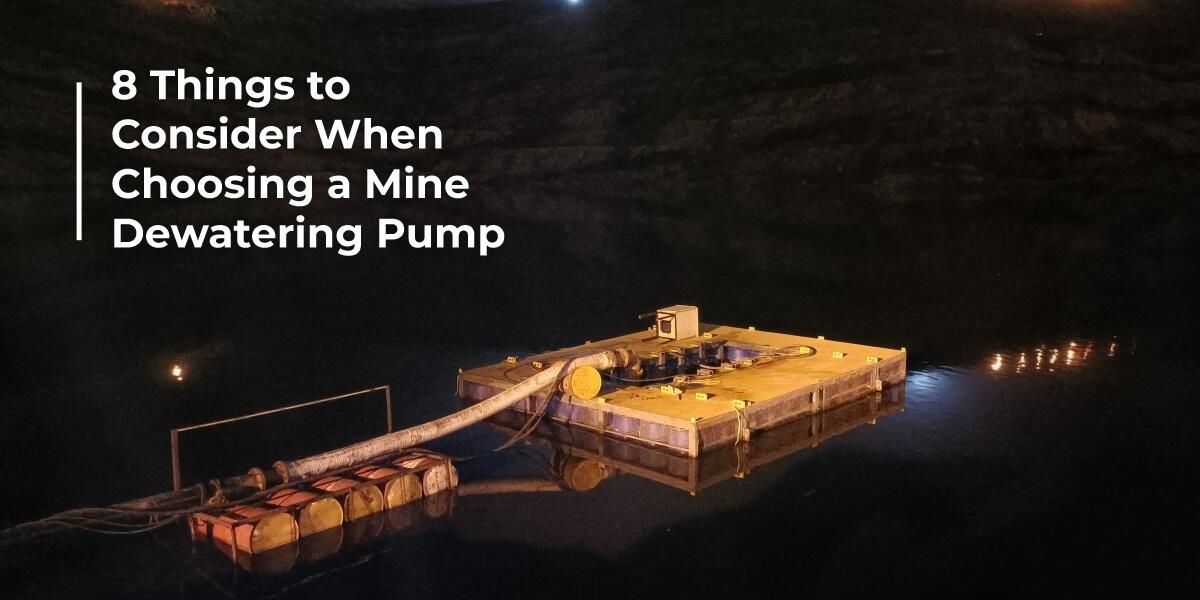

A suitable and adequate pump is vital to the mine’s success because for obtaining the precious minerals a correct and proper selection of a dewatering mining pump is crucial.

You must read this complete blog for the appropriate selection of the mine dewatering pump.

Dewatering pump for mines has variety of applications. Therefore, when choosing a dewatering pump users should choose equipment that is versatile, while remaining safe, productive, and trouble-free.

For example, in an application of mining, where water flowing into an underground mine is allowed to collect in sumps. From sumps it can then be pumped to the surface. Generally, this system pumps dirty water. This dirty water needs to be pumped continuously, barring a certain surge capacity in the system of sumps.

This approach prevents dry areas near the bottom of the mine, thus influencing mining procedure and efficiency.

When selecting such a system, following are five factors that can be considered:-

5 Things to Consider When Choosing a Dewatering Mining Pump

- Static Head – You need to determine the static head that any pump needs to overcome. The required flow will not be achieved, if the pump cannot produce enough pressure to overcome the vertical distance.

- Depth of the Underground Sump – The pressure that the dewatering mining pump needs to develop is the crucial factor while focusing on the depth of the underground sump.

- Differentiation between the water level and the pump’s suction

- Length of the suction pipeline

- Pump’s elevation above sea level

- Temperature

- Specific gravity

- Flow rate – When selecting a dewatering pump it is also important to determine the flow rate. The flow rate is the flow needed to remove the amount of water properly to keep the mine dry. At this stage, you must also consider, what style of pump is most suited for the application. For the self-priming pump, you must find out what is the length of the suction line. The size of the suction line of the pump must be equal to, or greater than, the size of the suction or inlet port. This is important to reduce the possibility of suction cavitation.

- Capabilities of the pumping system – The efficiency of the pumps may change, due to the nature of dewatering pumping. The pump’s performance may move away from the best efficiency point (BEP), as the pressure changes due to wear, or other factors. Flooding out or the loss of critical equipment and operational time could occur, if the pump selected is too small, or there are less number of such pumps. On the other hand, the motor could burn on the pump due to many starts per hour, if the pumps are too large. Because of many starts per hour, the motor will have no time to cool off before starting again. Thus, the pump, that is starving for water, experience suction cavitation.

- Efficiency – The users usually go for larger sizes of pumps, on the basis that they can cover a multitude of jobs, but efficiency is often sacrificed in doing so. To reduce fuel usage and operating costs, developments in technology are of great help. Newer types of pump have been introduced in recent years, that are specifically designed to reduce fuel consumption at times of low load and cope with fluctuating application demands. This is done without running up high-fuel costs or risking any kind of burnout.

- Versatility – One more point to consider when choosing a dewatering mining pump is its versatility. This means that users must choose a pump such that it is suitable for multiple applications. As a user, your priority should be taking a look at the design of the pump’s components and how they work together.

- Durability – Pumps work in extreme environments and thus, they need to perform reliably in such environments. Thus, it is important to select a pump that is fully tested and which is capable of withstanding tough and changeable working conditions as soon as it is turned on. One must see to it that pumps should not get clogged up. A pump will reduce the flow of water being pumped, if it gets clogged. Obviously, clogging affect performance and if such a pump if allowed to continue for an extended period of time then it could ultimately burn out.

- Ease of Service – Any time lost for maintenance and repairs can be catastrophic, when it comes to pumping fluids. One should choose pumps with a combination of long-service intervals and simple service. We suggest to select pumps that can be serviced in minutes, instead of hours, with easy access to all parts and consumables. Thus, when choosing a dewatering pump, the availability and simplicity of service pack is a major consideration.

The static pressure available in the system to force the water into the pump is the available net positive suction head (NPSHa). The type of the pump influences the NPSHa.

The NPSHa is affected by various variables relevant to the environment, which may consists of:-

You must first consider the required pressure the dewatering pump for mines needs to perform. To ensure continuous flow, every pump has a minimum NPSH requirement. This NPSH requirement depends on pump’s operating duty point. Thus, the net positive suction head available (NPSHa) must be compared to the net positive suction head required (NPSHr) when you select a dewatering pump.

It is ideally recommended that to prevent any risk of suction cavitation, NPSHa must always be more than NPSHr, ideally between 1-1.5 m safety margin.

Thus, we recommend that buyers must note that bigger is not always better and consider newer types of technology, than just replicating or repeating orders from the past.

You must also consider pumps that come with a range of accessories to enhance performance for changing applications. Such a pump with modular design can enable upgrades or changes to the existing pump without the need to replace it with a completely new pump.

Therefore, before selecting a dewatering pump the most important thing is, as a user, you should ask what steps the company or the manufacturer has taken in order to avoid clogging and as a result guarantee consistent performance.

Summing Up

The buyers should always discuss the application needs directly with their manufacturer when specific applications are considered. You must consider the key things discussed above when selecting a pump.

Are you ready to discuss about your mine dewatering pump? Do you want to discuss a few considerations listed above or you are stuck on any of those?

If yes, then get in touch with Perennial Technologies Pvt. Ltd.! Our team have worked closely with maintenance and site engineers and managers to ensure the optimal dewatering pump is selected. You can contact us if you too need help in selecting the best dewatering mining pump.