Introduction

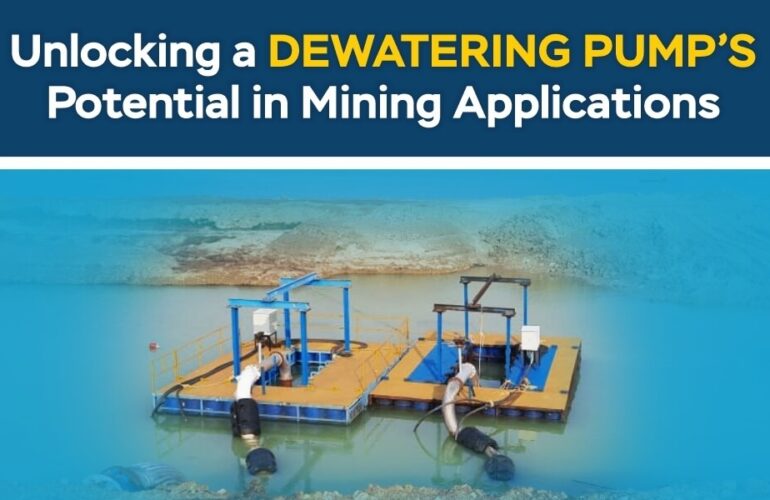

When water volumes become greater than anticipated at a project site, controlling groundwater can be unexpectedly challenging.

Dewatering is a technique that demands special consideration of both the construction techniques and hydrogeology like no other engineering task! Hence, here we will take a look at 7 questions for creating an effective dewatering system.

When excavating the spaces below the ground, water always comes up. Any construction foundation or structure or anything below the water table always requires some type of dewatering. Companies, engineering firms, and contractors often assume that one type of dewatering system will work on all projects.

Problems with Inadequate Dewatering

Do you know? If for a foundation or for a project, a wrong dewatering method is chosen or if dewatering pumps for rent are not considered at all then the results can be costly in terms of time, cost, reputation, and safety.

If the dewatering system proves to be inadequate then the work may come to a halt. If everyday work doesn’t get done, then users may lose money and fall behind schedule. This causes costs to increase.

The companies may need to rent additional excavators, loaders, and dump trucks, to meet the project deadline and avoid penalties. There can be extra fuel costs needed too. Wet or muddy job sites pose safety issues for crews too, especially when water compromises the stability of slopes. Water from the ground or surface water due to various rain events can damage construction and other equipment and will result in reduced productivity. Water could also destroy work that has been performed in the worst cases.

Have You Planned For All the Possibilities?

It is important to consider all the possibilities when choosing the right dewatering system. One has to consider the current as well as future possibilities or conditions. One must know that the excavation depth, the soil types, and buildings and infrastructure surrounding the site can affect a project. To determine the best method, taking a detailed soil boring to understand the soil components and performing a pump test are very important.

You must anticipate weather events also. An example to consider is, a contractor wanted to put a sewer line and an engineer suggested a single wellpoint system for this project for dewatering. This proved to be inadequate to control flooding when it rained.

Thus, by installing well points on both sides of the excavation an equipment rental company had to create a backup dewatering system, and also to handle the surface water it had to install additional sump pumps. All these things worked well and dried out the project area enough so that the contractor could work. Still, the subcontractors had to work around several additional 6-inch pumps in spite of all of this. If these weather crises had been predicted some time prior, the problem might have been avoided.

It is also very important to factor out the tidal system and water fluctuation for waterfront projects. Otherwise, it would result in additional labor costs and time delays too!

7 Questions for Creating a Dewatering System

So, what are all those questions that you will ask for creating an effective dewatering system? Let’s have a look at the 7 questions given below for creating a better and more effective dewatering system:-

- Does the dewatering site show any signs of instability or soil erosion?

- How far is the water table below the surface?

- Is there a need to lower the water level in advance of excavation?

- Are there any nearby buildings or structures that could be impacted due to this and if yes how will they be protected?

- Will standby equipment be needed and available?

- In case of continuous dewatering will pumping be needed?

- When the project is over, what impact will rewatering have on the site and the surroundings?

Other than all of these questions, the dewatering plan should also cover details about closing and removing the dewatering systems and whether or not it follows local and state procedures to avoid contaminating groundwater.

Is the Wellpoint System the Only Solution?

Are wellpoint systems the only solution for all dewatering projects? Certainly not! Wellpoint dewatering systems are often suited for dewatering when digging shallow foundations, performing utility work and trench work, etc. It is advisable that contractors should ask the engineers whether other dewatering methods may be more appropriate for the site. For example, in a scenario when the excavation goes below 26 feet or if there is a need to pump out large quantities of groundwater, a deep well system might be the best.

Conclusion

The right dewatering pump and an effective dewatering plan decrease the risk of unnecessary delays and increase jobsite safety. Selecting and designing a dewatering method is partially an art and partially a science which is based on investigation of the area including soil and hydrology. Experience too matters a lot when choosing a dewatering method.

A company that has experienced a variety of challenges with various dewatering techniques is best positioned to suggest and design the right system for the project. It can be said that the investment made in a company with dewatering expertise proves itself to be successful when the actual jobsite stays dry for work to continue despite groundwater situations.

At Perennial Technologies, we help and guide you with the selection of the dewatering method. We can suggest the best dewatering system as per your needs and can also provide you with dewatering pump rental solutions!

We provide dewatering pumps for rent at cost-effective prices. The dewatering process becomes easier with our dewatering pumps for mines.