Introduction

Do you want to ensure a profitable beginning to your construction project? Choosing the correct dewatering method is very essential for this. This will ensure a profitable beginning to any construction project.

Undesired water at a construction site can bring many problems such as increased costs, safety risks, and delays to your project. Therefore, dewatering is necessary.

Dewatering helps to firm the soil, reduces slip hazards, eliminates the release of toxic materials into the surrounding environment, and minimizes equipment damage. As per the requirement, one can use dewatering pumps for rent.

One must consider the three most common methods for dewatering a site:- open pumping, slurry pumping, and pre draining before starting any project.

Open Pumping

The water is allowed to flow freely from the soil into the site as it is excavated in the open pumping method. Then, the water is collected either into ditches, sumps, or drains. The water is pumped out of the excavation into these sumps, ditches, or drains and then it is emptied into a suitable collection site.

Slurry Walls

A slurry wall is a civil engineering technique. This technique is used to build reinforced concrete walls that allow the construction of a foundation. Such walls are made in areas with a high groundwater table or of soft earth close to open water. This method is used for the construction of structures placed into bodies of existing waters and for extremely deep excavations. These types of walls are generally built surrounding open cuts and tunnels.

Pre Draining

In the Pre draining method of dewatering, the soil can be drained before excavation. This is done with the help of ejectors, vertical sand drains, vacuum wells, wells, or well-points, etc. It is a fact that most of the sites favour well-point dewatering. Well-point dewatering is popular among contractors for its overall efficiency and adaptability, even though each site differs in terms of soil, hydrology, and construction conditions.

Data Collection and Decision Making

Site managers must collect the following information before implementing a well-point dewatering solution:-

- Soil’s nature

- Hydrology of the groundwater (the movement, and distribution of the water, and the quality of water present)

- Size and depth of the planned excavation

- Ground support and proposed methods of excavation

- Foundation details of any existing structures

- Design and function details of the structure to be constructed

- Planned construction schedule

There is a measurement known as TDH, total dynamic head, which measures the total height that a fluid is to be pumped upward, which accounts for the amount of friction loss in the pipe. Being a contractor, this total dynamic head (TDH) involved in the dewatering application should be considered.

It is also an observation that a small excavation with unusual soil can create greater dewatering difficulties than a larger, deeper job in well-graded medium sand.

Once contractors gain and do an analysis of this information, they can make a decision if a well-point application is suitable to the site’s needs or not.

Well-Point Systems

We have seen that well-point systems are the most preferred dewatering systems. These systems keep the foundation dry during flooding and rain. Well-point dewatering systems dewater water-bearing soils, such as gravel and sand. Well-points help stabilize soil and help supply water for municipalities and industrial plants.

A well-point system consists of a series of well-points that run parallel to the site. Well-points are nothing but small-diameter tubes with slots near the bottom. These well-points are inserted into the ground and placed at the calculated spacing and depth. They are placed by self-jetting into the ground before the excavation begins.

There are various soil conditions. Depending on them, some soil conditions require pre-drilling or hole-punching and sand casing before the well-points can be installed. These well-point tubes are then connected to a header pipe with risers and/ or swing piping. A dewatering pump is then connected to the header pipe which creates a vacuum in the pipe. This vacuum helps to pump the water in the soils of the construction site to the discharge area.

To ensure a stable foundation, the well-point system must operate 24/7 until the construction project is completed. For a successful project, the selection of a quality pump and reliable project support is necessary. The height to which the water can be drawn is limited to about 18 feet, as the vacuum created by the pump is limited to zero bar (absolutely no pressure). The well-points are then installed in stages, with the first stage bringing the water level down to 18 feet when the construction plan requires a foundation depth or stability greater than 18 feet. Then, the next stage is installed at the 18-foot lower level. This reduces the water level to the required depth. An additional installation of well-points can handle any water that may trickle between these well-points.

The table given below provides a small review of the characteristics that make well-point dewatering systems the most reliable choice for contractors.

Conditions | Well-point |

Soil | |

Silt and clay sands | Good |

Clean sands and gravel | Good |

Stratified soil | Good |

Clay or rock at subgrade | Fair to good |

Hydrology | |

High Permeability | Good |

Low Permeability | Good |

Proximate Recharge | Good |

Remote Recharge | Good |

Excavation | |

Shallow (Less than 20 feet) | Ok |

Deep (Greater than 20 feet) | Multiple Stages |

Cramped | Interferences |

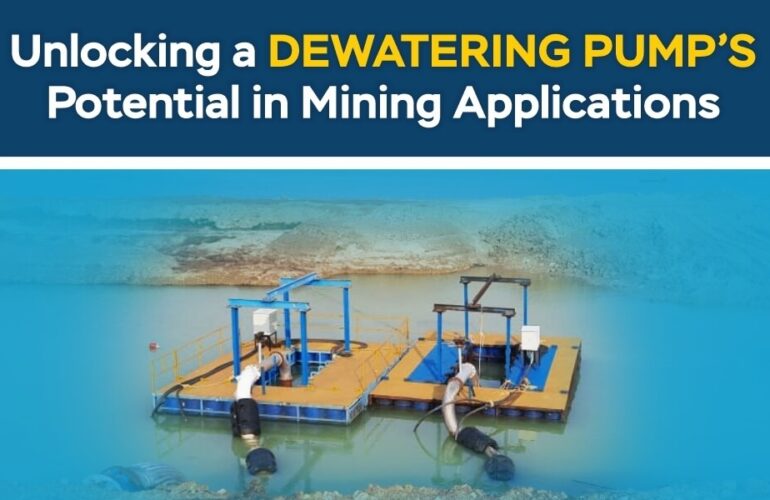

Reasons to Consider a Well-point Dewatering System

There are 3 main or primary reasons to consider a well-point dewatering system:-

- Adjustable as per Specific Project Needs

Construction dewatering adapts more effectively with deep wells than sump pumps. Sump pumps are excellent for shallow excavations rather than deep excavations. They are costly because you must invest in different units for every individual project.

Well-point systems on the other hand can adjust to specific project needs. Consider an example, a single-stage well-point system is suitable for shallow excavations, and then you can add second-stage well-point systems if you are going to deal with deeper excavations. These systems can effectively handle low silt soil pressure too while offering optimal performance in sandy soils. Hence, most suitable dewatering pumps for construction are well-point pumps.

- Minimization of Excavation Costs

Well-point dewatering systems can adapt to various site conditions, thus you will not require investing in other specialized dewatering systems. This helps to lower the total cost of your project to a greater extent. Also, this is beneficial because you will spend less money training workers on how to run a single dewatering system than multiple systems.

- Well-points are Quick and Easier to Install

Construction on high groundwater tables is time-consuming. In such projects, it is necessary to avoid dewatering systems that demand plenty of installation time, because such systems will lengthen the timeframe of your project. To avoid this problem, it is important to consider effective solutions like well-point dewatering systems that are easier to install and set up. These systems require less setup time and you only need to connect smaller wells to a primary header pipe having a suction pump. Also, they don’t demand more labor during installation.

Thus, from the above illustration about well-point dewatering systems, it is clear that they are useful for most site dewatering needs and hence, preferred!

We are the best dewatering pump rental providers in India. If you are looking for a dewatering pump on rent near me, then you can contact us!